Key Considerations for Successful Network Deployment in Manufacturing Environments

July 09, 2020

If you're adopting IIoT practices and preparing to extend your physical network into a manufacturing environment, you likely have some concerns. Although your physical networking requirements are unique to your facility and environment, you can find comfort in the fact that there are a few universal concerns you should take into consideration. This means you're not alone. In addition, it's important to know there are ways to address them.

Floorspace is limited

Floorspace is limited

Floorspace in the manufacturing environment is limited. It is firstly reserved for manufacturing equipment and secondly for material logistics. This may not leave much or any space for networking.

Overhead may be the best option. It may offer the least obstructed path for cables, be high enough to avoid

incidental damage from material handling and provide excellent physical security because a lift or ladder is needed to reach equipment.

The need for flexibility

As mentioned, the manufacturing environment is fluid. Manufacturing equipment changes and floorspace is reset to new production practices and models. This is a continuous process. Additionally, as an organization

increases the amount of integrated automation, faster network connections are required to keep equipment connected and synchronized correctly.

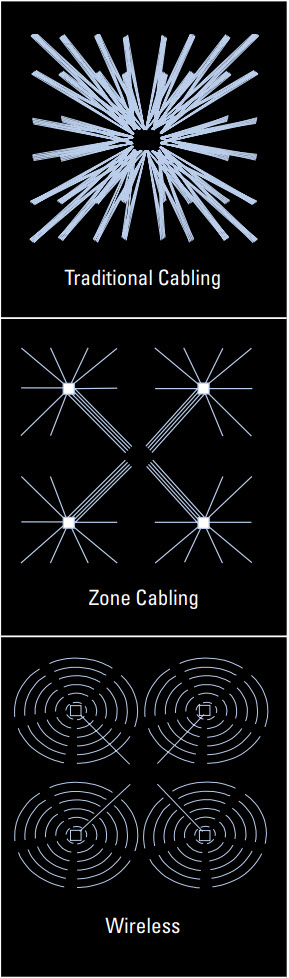

Zone cabling is the practice of dividing the space into zones and supporting connections in each zone from a centralized telecommunications enclosure. This allows easier moves, adds and changes and typically limits cabling and networking changes within the affected zone.

Environmental impact on IT equipment

The manufacturing environment is usually not as clean as an office environment. It may be dirty, wet, or otherwise expose sensitive networking equipment to environmental hazards. It’s certainly feasible to store networking equipment in the manufacturing environment, but it is also necessary to then create protected spaces for equipment using industrial/environmental enclosures.

Industrial enclosures protect equipment from dust and liquid, can be modified to support traditional computer and networking equipment instead of panel mount automation electronics, and can be conditioned to provide the right operating temperature for equipment.

To learn more about what to consider and how to overcome the challenges of extending the network into your manufacturing environment, read a white paper.

Also, be sure to leave your questions and comments or unique physical network requirements in the comment box. We'll have our experts address them.

Posted by Brittany Mangan, Digital Content Specialist at 7/9/2020 6:40:23 AM