Cart

30026-E01

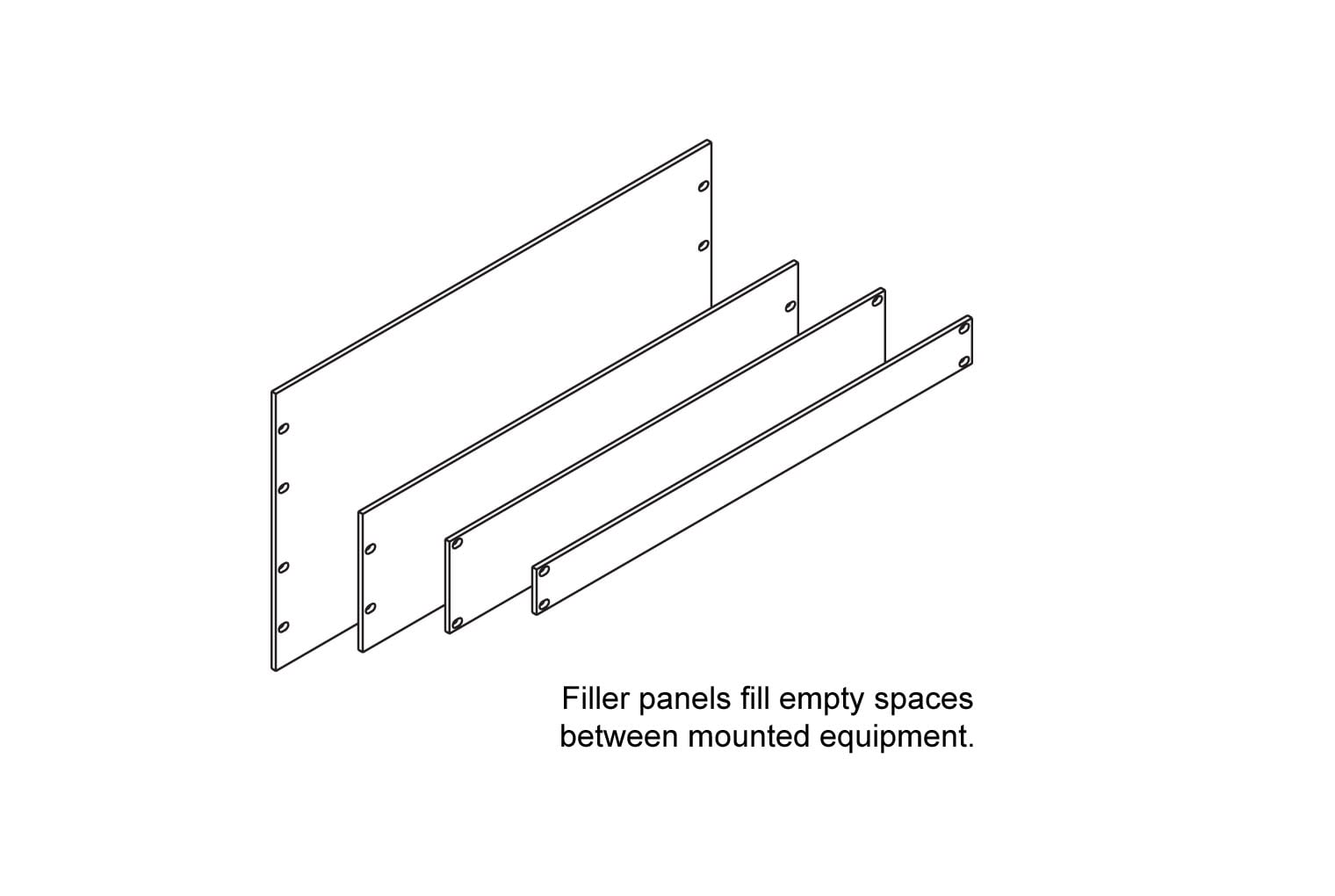

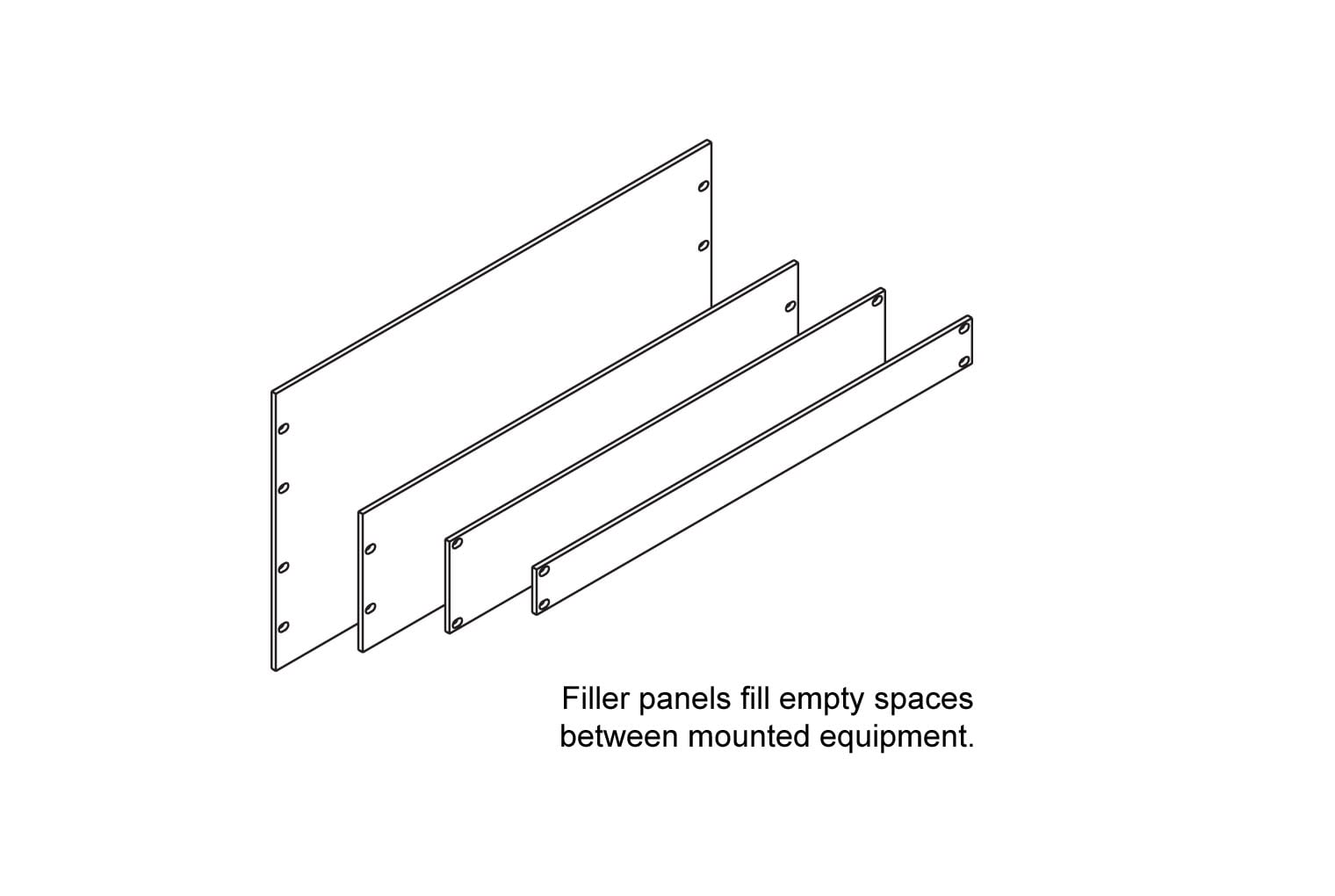

Filler Panel; 1 RMU; 1.72"H (43.7 mm) x 19"W (482.6 mm) x 1/8"D (3.18 mm); Glacier White

| Height | 1.7" (44 mm) 1U |

| Width | 19" (483 mm) |

| Type | 1/8" (3.18 mm) Thickness |

| Color | Glacier White |

Product Description

For airflow control and/or equipment mounting, fill empty spaces between mounted equipment.

Product Information

Key Benefits of Using Filler Panels

Filler panels are engineered to fill empty spaces within cabinets, eliminating unwanted gaps that disrupt airflow. By creating a continuous enclosure surface, they help maintain consistent pressure differentials across equipment racks. This simple addition supports overall system reliability and reduces the risk of component overheating. In the context of thermal management, filler panels act as passive cooling accessories that complement active airflow strategies. They work with aisle containment and perforated floor tiles to direct cool air precisely where it is needed. The result is a more uniform temperature profile that protects high‑density servers and networking gear. Effective airflow control depends on minimizing turbulence and short‑circuiting of conditioned air. Filler panels prevent cold air from escaping through unused rack spaces, ensuring that chilled air reaches the front of each device. This improves the efficiency of fans and reduces overall power consumption for cooling. Installation of filler panels requires no special tools and aligns with standard 19‑inch rack dimensions. The panels snap into place and can be re‑configured as equipment layouts change, providing flexibility for evolving data‑center designs. CPI supplies detailed mounting instructions to streamline deployment for technicians. When data‑center operators adopt filler panels, they observe lower inlet temperatures and extended hardware lifespan. The panels contribute to measurable energy savings while supporting CPI's commitment to rapid product customization and global availability. For additional guidance, CPI's technical support team offers expert consultation on optimal thermal‑management configurations.