BICSI & ANSI/TIA Secondary Bonding Busbars

Explore Sizes & Options

| Add to Cart Add | |||

|---|---|---|---|

13622-010 | 10" (254 mm) | $170.33 | |

13622-012 | 12" (305 mm) | $187.09 |

Product Description

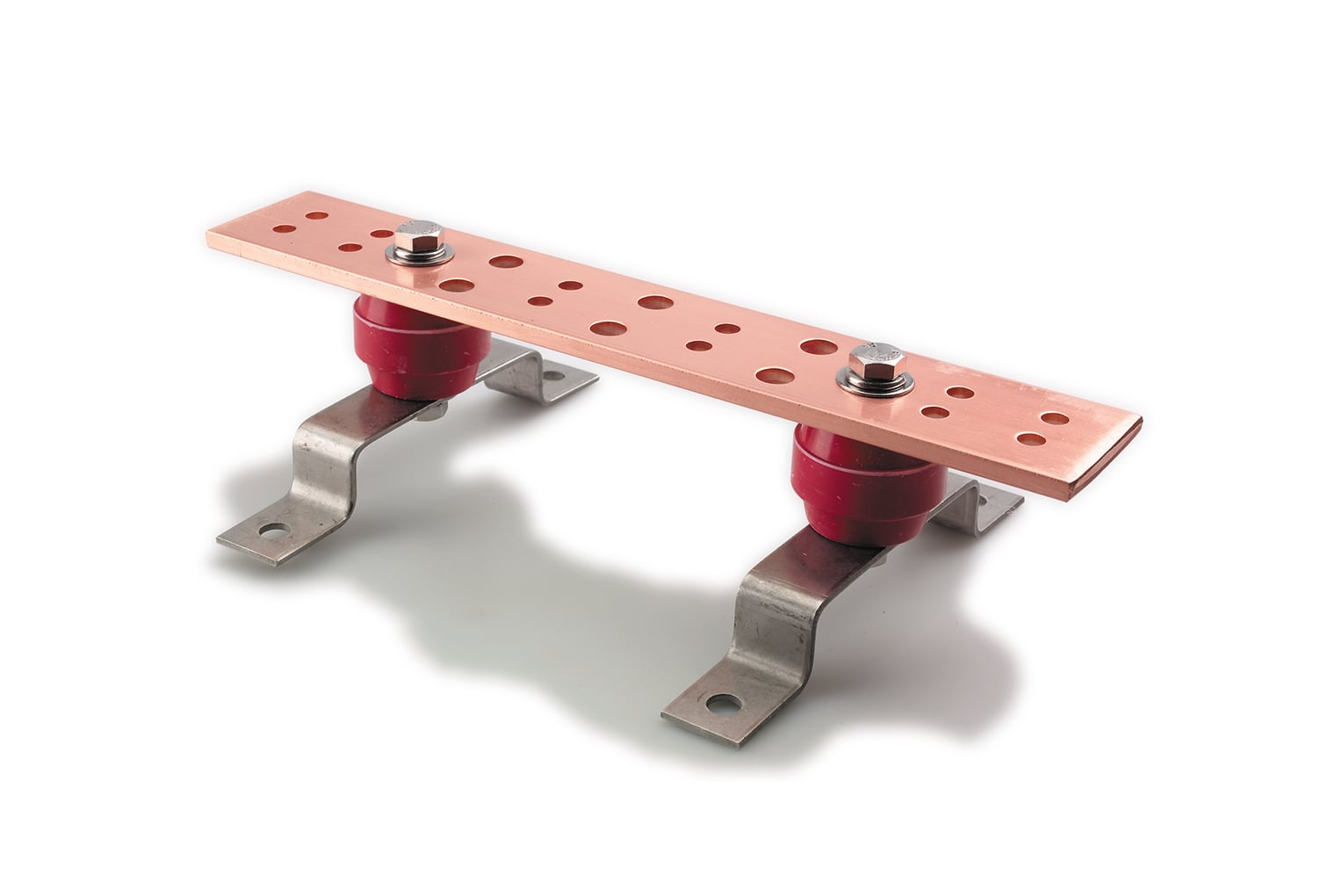

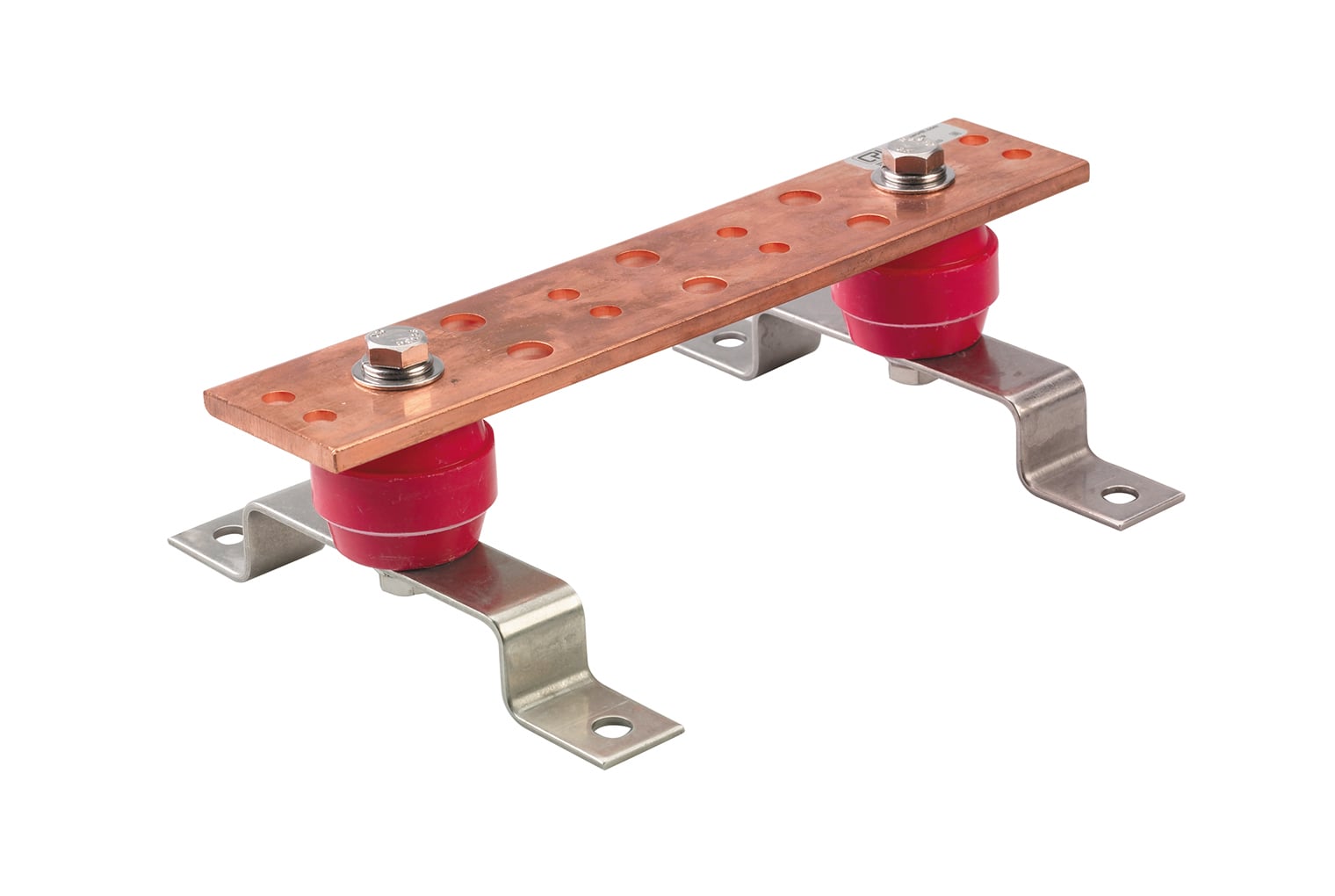

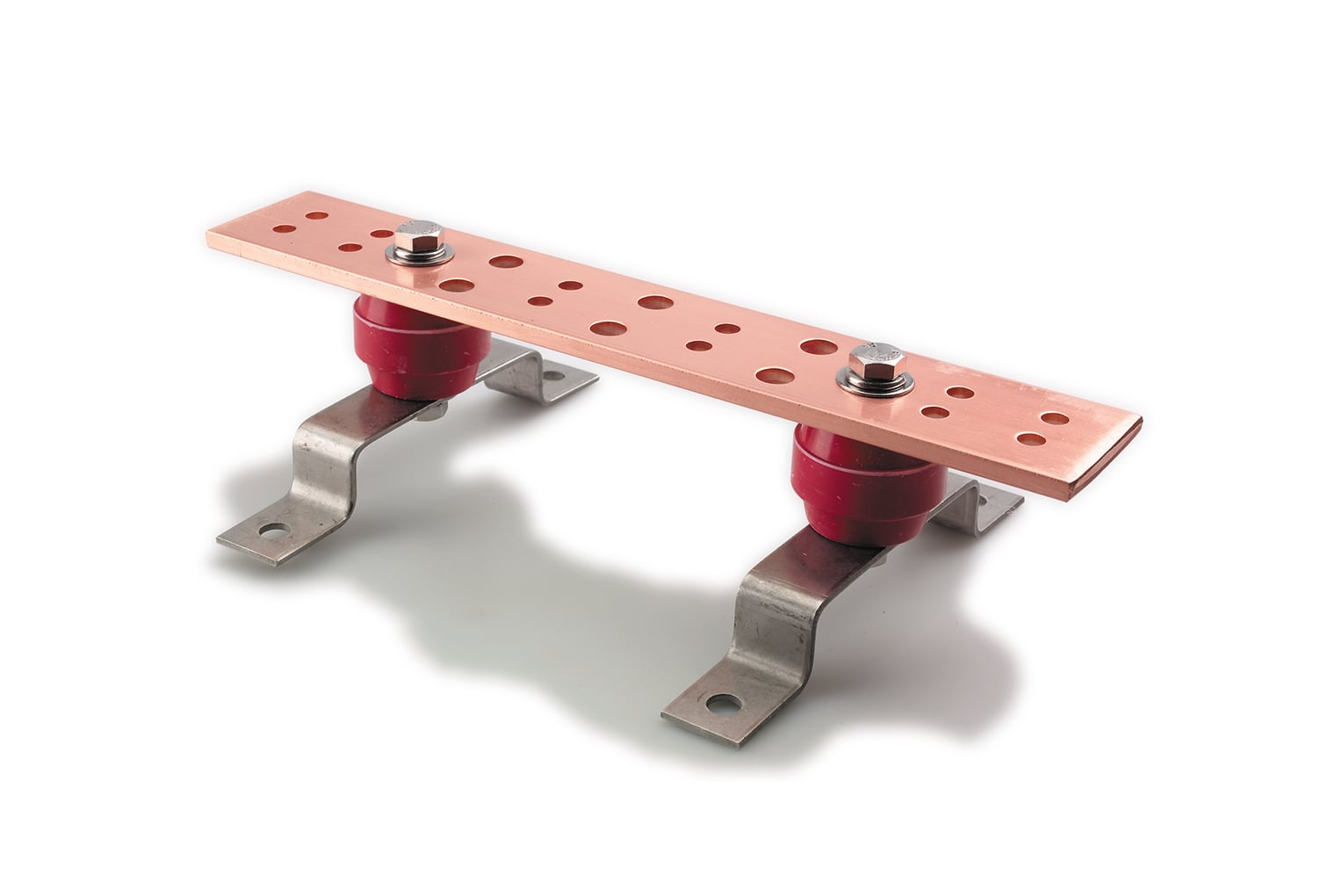

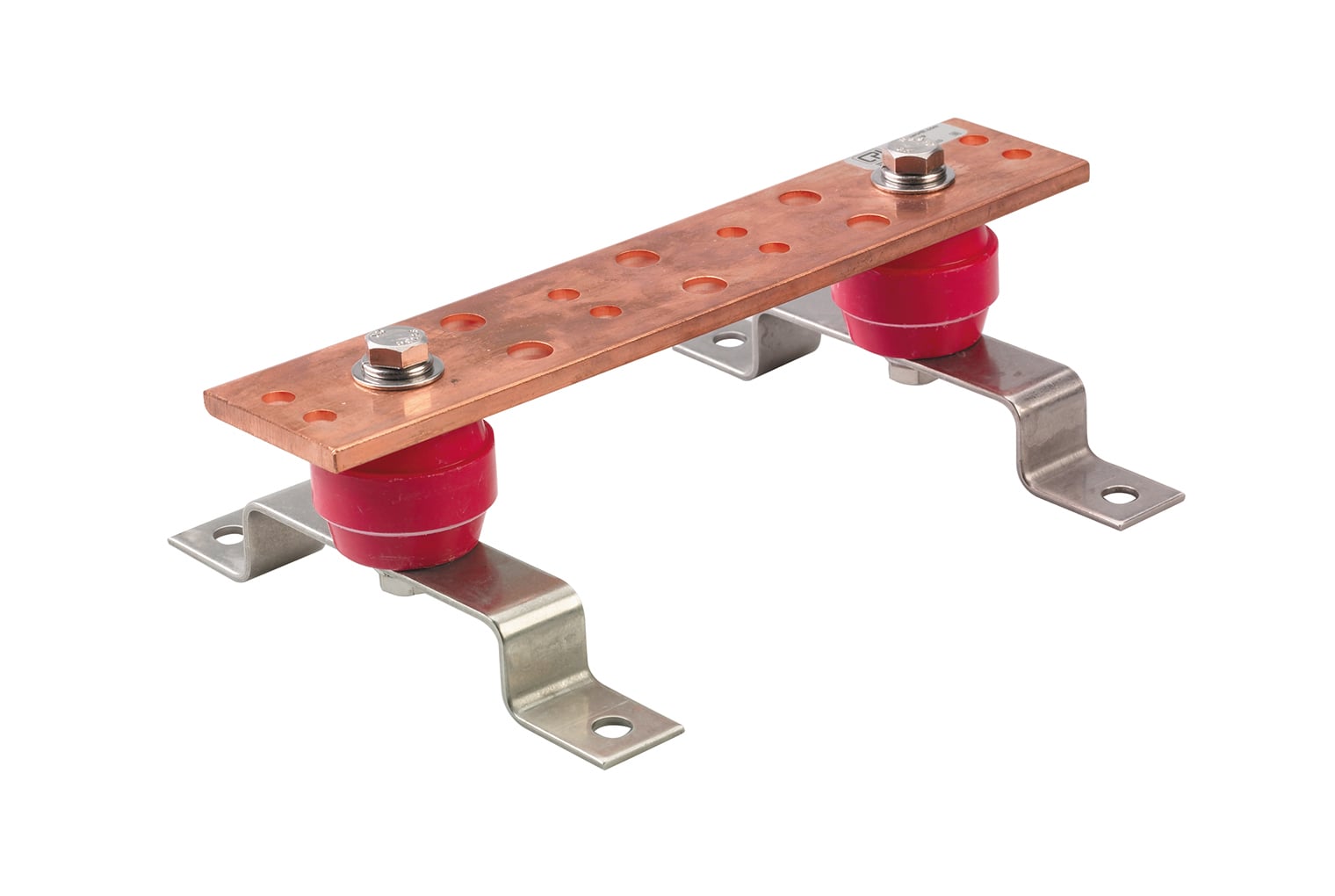

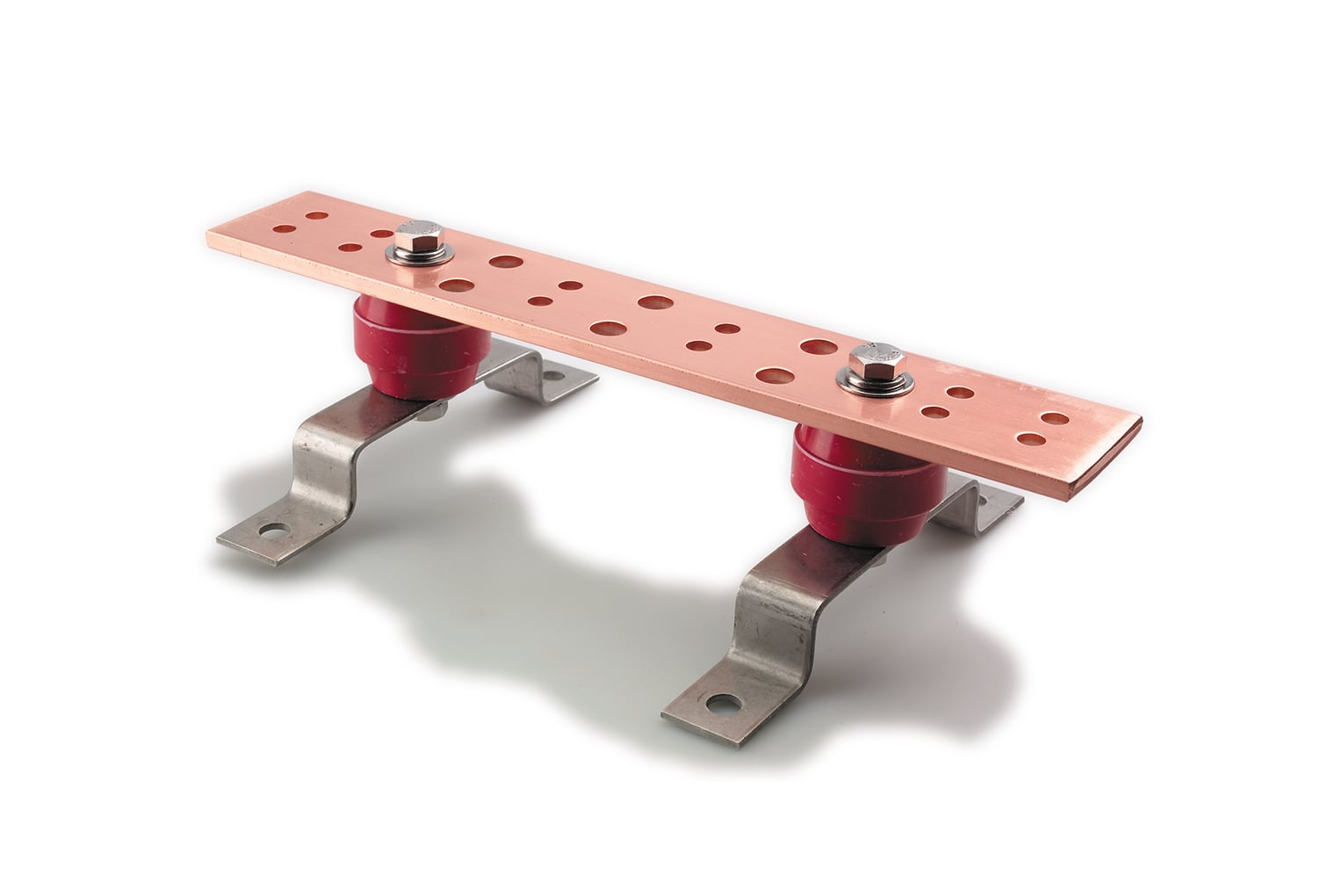

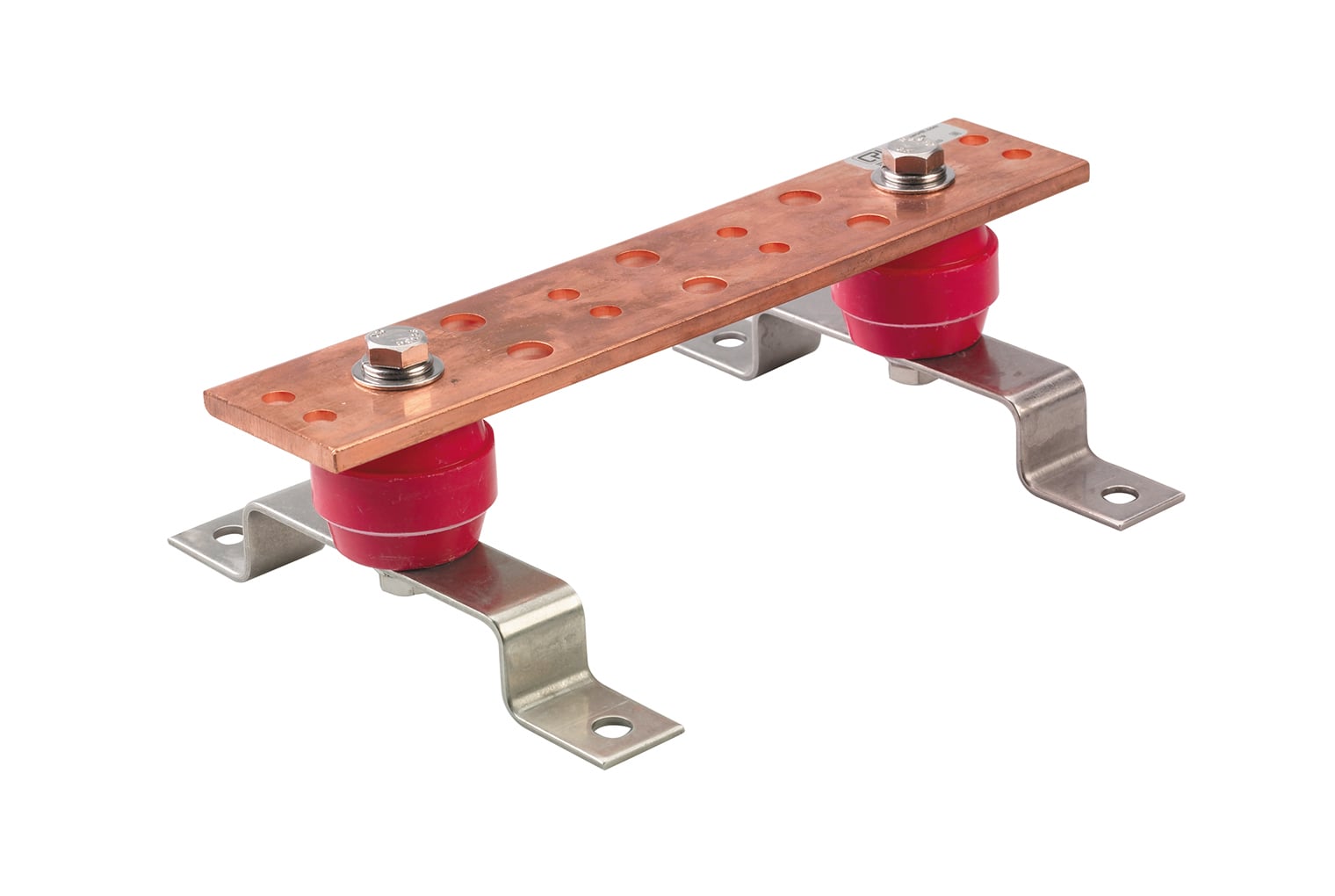

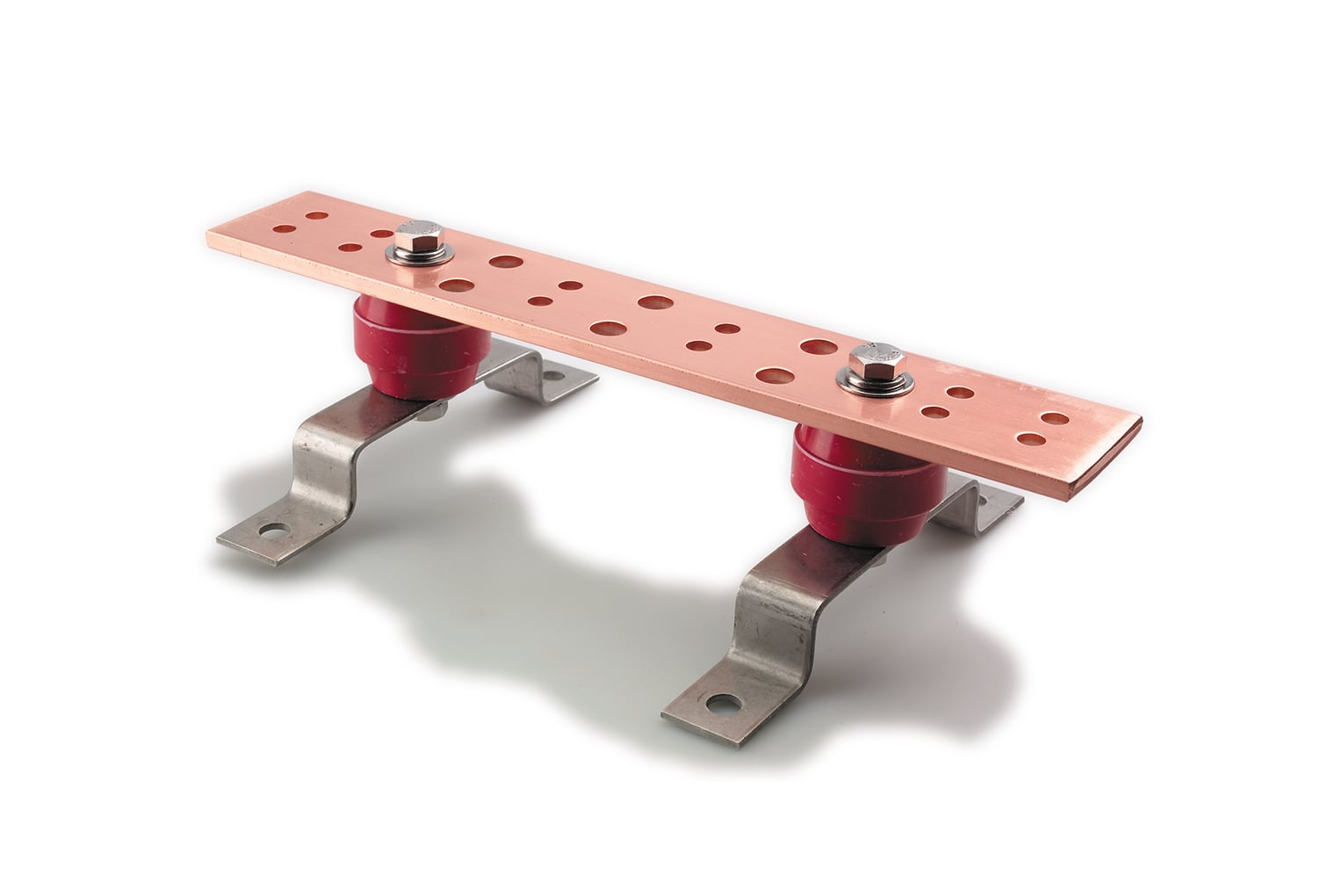

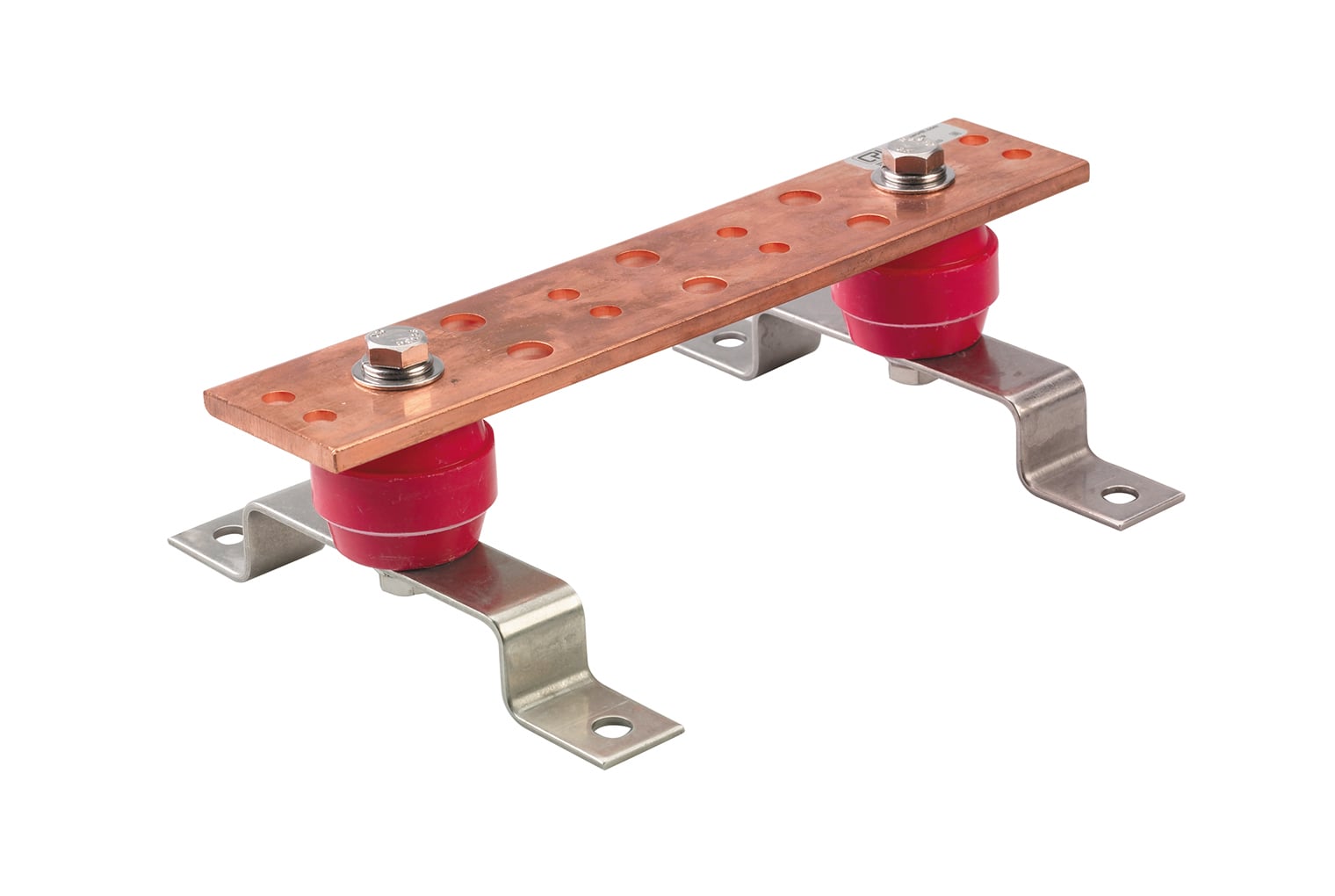

Secondary Bonding Busbar (SBB) provides a central bond attachment point for ICT systems located in the data room.

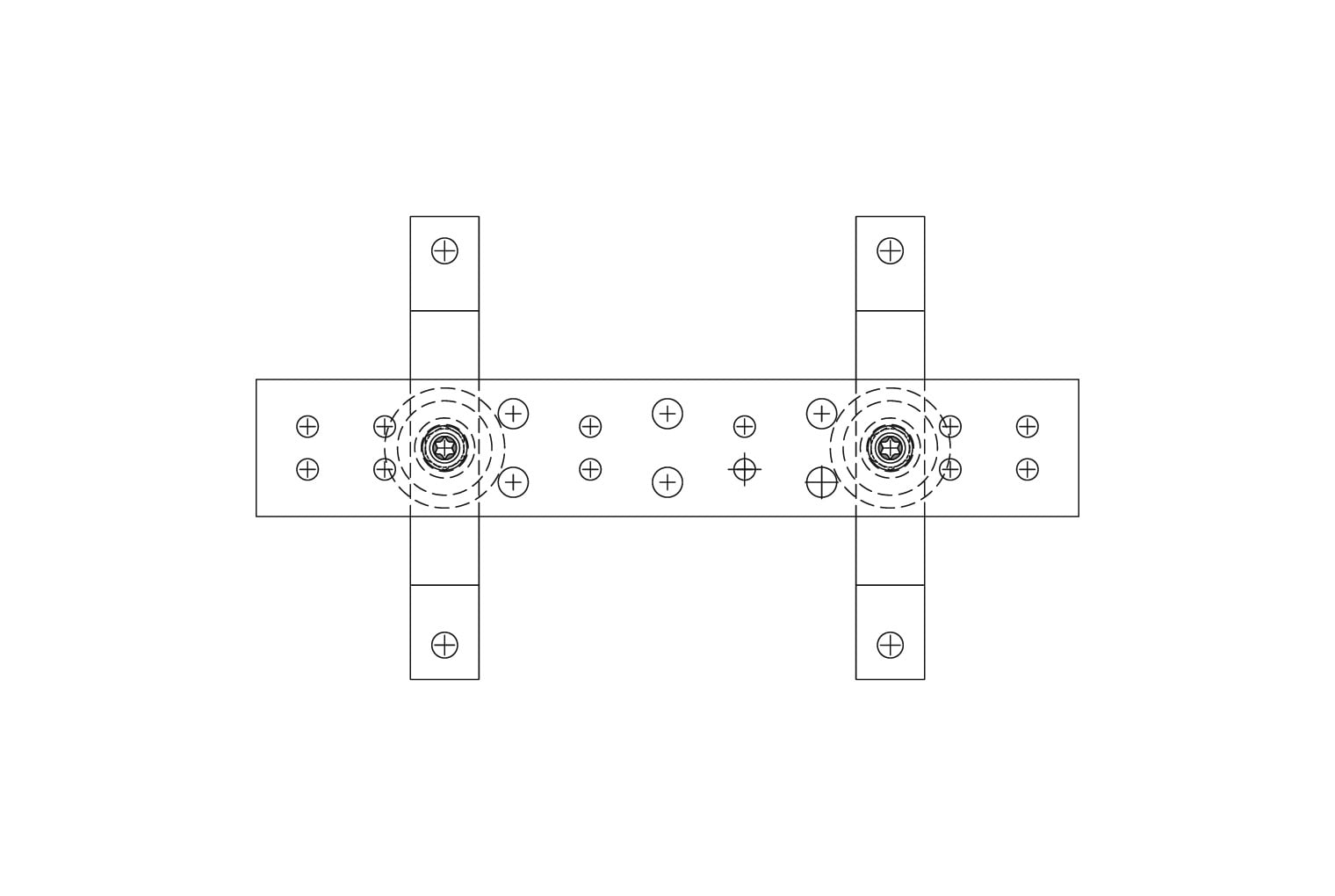

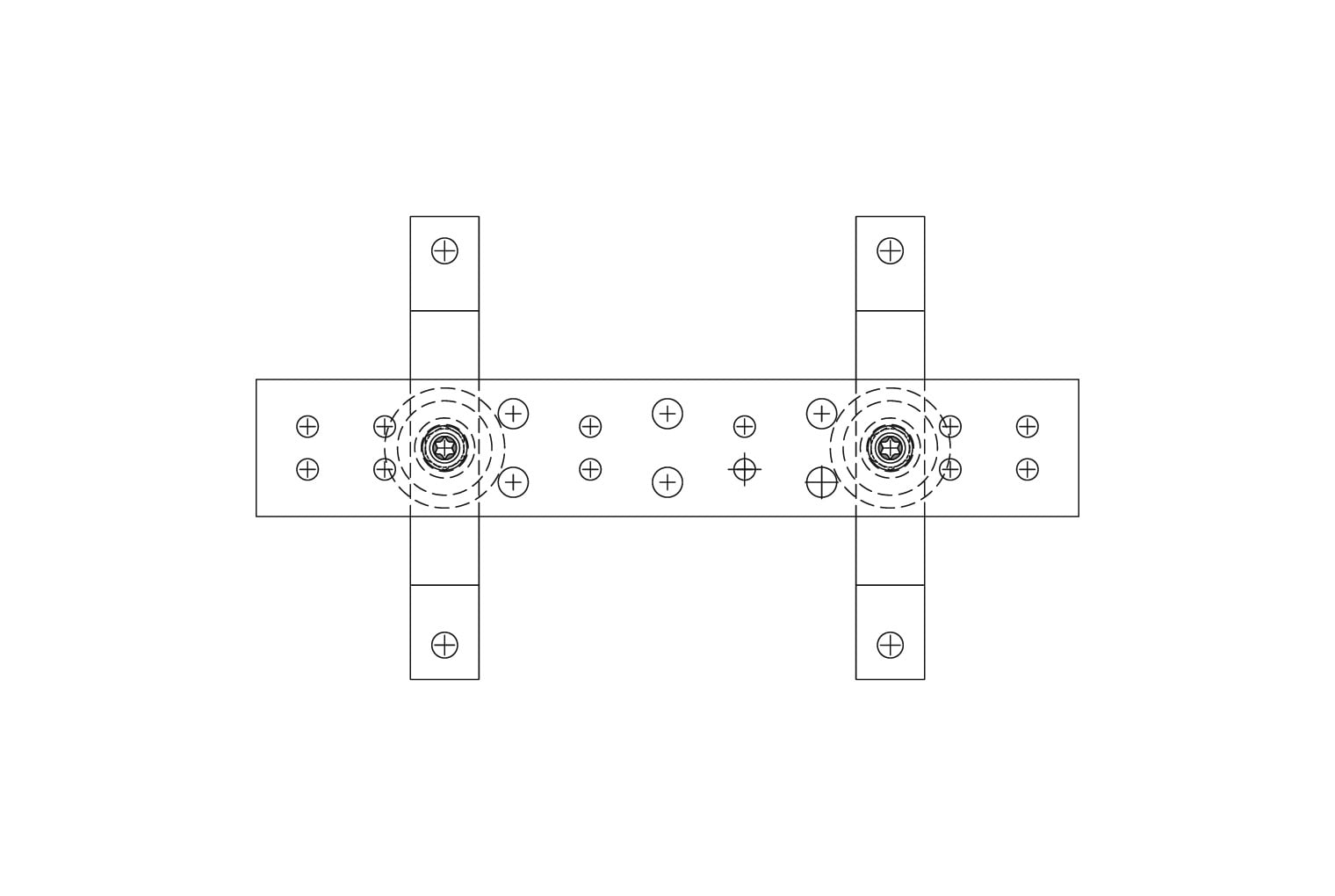

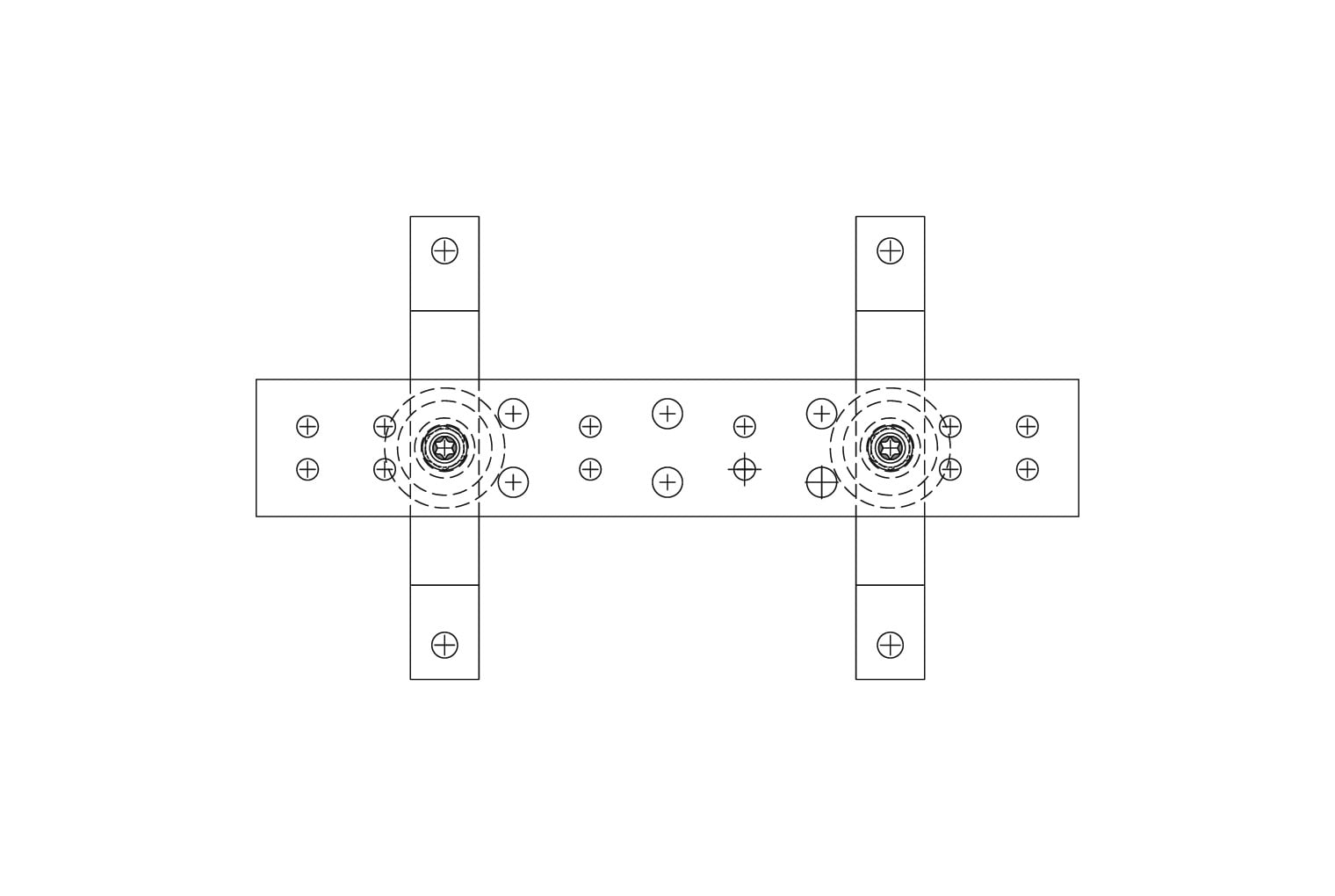

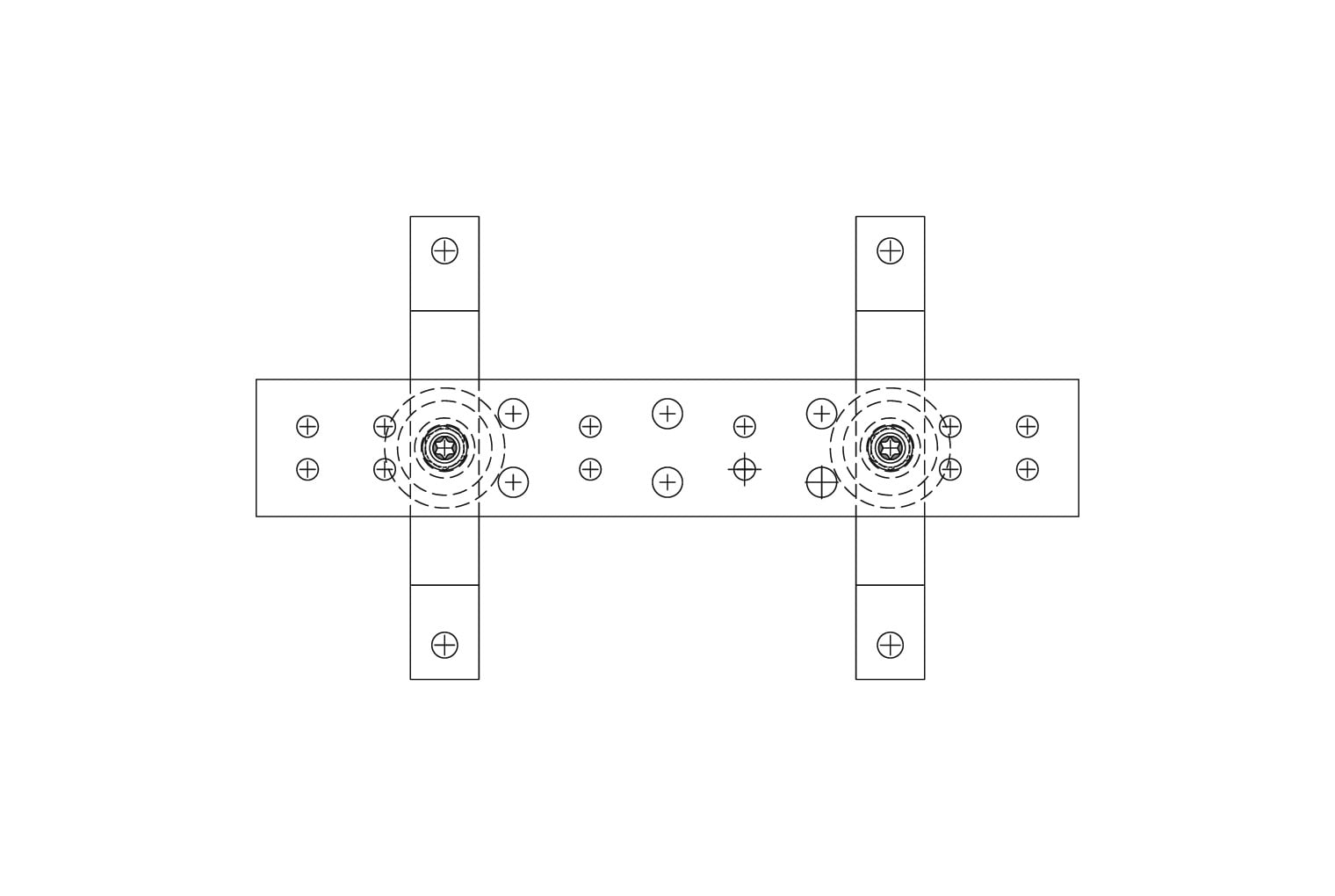

Hole patterns on Busbars accommodate two-hole lugs per the recommendation of ANSI/BICSI N3-20 and ANSI/TIA-607 standards. Insulators electrically isolate Busbars from the wall or other mounting surfaces, thereby controlling the current path.

Key Features and Benefits

- Mounting brackets are manufactured from high-quality 300 series stainless steel with 3/8” (9.53 mm) diameter mounting holes spaced 5.75” (146.1 mm) apart

- Busbars mount on the wall, floor or ceiling

- Ships preassembled

- Sold individually

- UL Listed, File E236184, Category KDER (US), KDER7 (Canada)

- Busbar assemblies with lug kits also available

- Other configurations available on request

Product Information

Design Tools

Key Features of ANSI/TIA‑607 Compliant Secondary Bonding Busbars

Chatsworth Products (CPI) offers a complete line of secondary bonding busbars designed for modern data center environments. Each busbar complies with ANSI/TIA‑607 requirements and provides a dedicated grounding point for ICT equipment. The secondary bonding busbar enhances system reliability while meeting BICSI grounding and bonding guidelines. The busbars are fabricated from 300 series stainless steel, delivering corrosion resistance and long‑term durability. Mounting brackets feature 3/8‑inch (9.5 mm) diameter holes spaced 5.75 inch (146 mm) apart to accommodate standard lugs. All units ship pre‑assembled, reducing on‑site labor and minimizing installation errors. Installation options include wall, floor, or ceiling mounting to suit a variety of enclosure designs. Optional lug kits enable quick connection of bonding conductors without additional welding. The modular design allows multiple busbars to be linked for expanded grounding networks. The design follows the hole‑pattern recommendations of ANSI/BICSI N3‑20 and ANSI/TIA‑607 standards, ensuring consistent performance across jurisdictions. The assemblies are UL® listed under File E236184, Category KDER (US) and KDER7 (Canada), providing verified safety certification. Compliance with these standards simplifies regulatory approval for secondary grounding projects. Detailed specifications are available in the downloadable spec sheet, and digital design files include BIM and Visio stencils for seamless integration into CAD workflows. CPI's expert consultation services can assist with custom configurations and optimal placement within complex rack systems. Selecting a CPI secondary bonding busbar guarantees high‑quality grounding that protects critical infrastructure.