Evaluating Regulatory Approvals for Information Technology Products

October 15, 2020

Most organizations within the United States fall under the purview of Occupational Safety and Health Administration (OSHA). OSHA requires that all electrical products deployed in the workplace be approved by a Nationally Recognized Testing Laboratory (NRTL).

In the U.S., Underwriters Laboratories (UL®) is the single most accepted NRTL and their certification mark appears on 22 billion products annually. UL’s comprehensive knowledge of the regulatory requirements impacting product performance, construction and composition, engineering and subject matter expertise help develop global testing programs for a wide range of regulations.

UL also provides increased visibility and business intelligence needed to proactively mitigate risks for compliance, understands how regulatory demands and industry standards apply to electrical products, and supports smart, confident decision-making. They partner with and evaluate products for compliance and conformance to applicable regulations, standards, and specifications. As a member of the international CB (certification body) scheme, UL allows vendors to gain global and country specific compliances, a parameter that’s being required more often by more organizations as businesses go global.

When evaluating information technology (IT) products, there are two primary criteria that an organization should check for:

- Is the product actually “UL certified” vs “Tested to UL standards”?

- What specific UL standard does the equipment comply with? UL 60950 or UL62368.

UL Certified vs. Tested to UL Standards

Standards for IT equipment within the U.S. have been developed by UL working in collaboration with the International Electrotechnical Commission (IEC).

A product certified by UL carries the UL logo and it means that it has been tested by UL themselves. UL performs comprehensive testing to ensure that the standard is met in its entirety and they continue to audit the approved factories on a regular basis to maintain and renew the certifications.

Several vendors choose to use other NRTL’s to test to the standards set forth by UL. These vendors list their products as “Tested to UL standards.” The testing is done per the interpretation of the standard by the NRTL but there is certainly ambiguity within that approach and in some cases, the standard is deemed to be met based on the major components of the design being “UL recognized.” This approach may sometimes neglect the safety issues that arise out of all the components intertwined within a complete system.

UL 60950 vs UL 62368

UL 60950 has been the standard in the U.S. since 2007 for IT products with a rated voltage not exceeding 600V. Like most standards set during this timeframe, it is by nature a prescriptive one. These types of standards focus on the methods used to build a certain product—it covers what type of components to be used and dictates certain conditions around the use of those components within a system.

UL 62368 is a newer standard that first came into existence in 2012. The coverage of this standard extends to IT as well as audiovisual equipment with a rated voltage not exceeding 600V. This standard supersedes UL 60950 and all component manufacturers are expected to transition their products to the new standard by December of 2020.

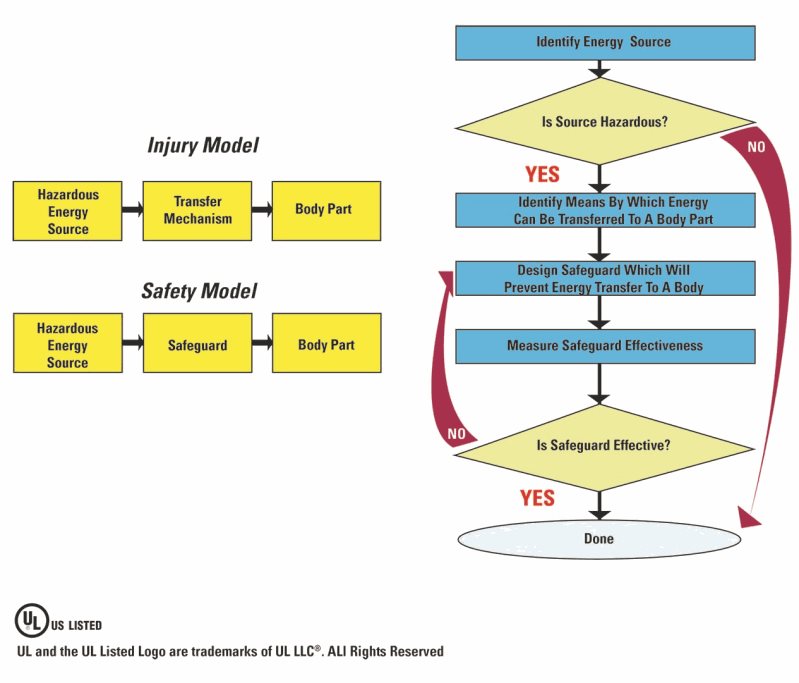

Adherence to UL 62368 provides some distinct advantages. This standard draws on the principles of the more modern hazard-based standard engineering (HBSE) practice. Within the realm of UL 62368, a hazard-based approach includes four distinct steps:

- Identify energy sources within the system

- Classify energy source based on its hazard potential

- Identify and design safeguards against the hazards

- Measure the effectiveness of safeguards

While UL 60950 assumes a user to be an “operator” or “service personnel,” UL 62368 defines a user as any “ordinary person,” “instructed person” or “skilled person.” UL 62368 also broadens the definition of a “fault condition” to include any non-normal condition that is not the result of a component or part fault. As a result, this performance-based standard is distinctly more stringent and thorough than UL 60950 in several ways.

Examples of Test Differences Between UL 60950 and UL 62368

| Description |

IEC 60950-1 |

IEC 62368-1 |

| Cap Discharge |

Test done at 240V~ and between line and neutral.

Test to be done under the normal condition.

Discharge voltage to be measured at one second after disconnection for pluggable type A equipment, and 10 seconds after disconnection for pluggable type B equipment.

The limit is 37% of the peak voltage at the disconnection point.

|

Test done at 240V~ and between line and neutral as well as line and ground and finally between neutral and ground.

Test to be done under both normal- as well as under single fault condition.

Discharge voltage to be measured at two seconds after disconnecting.

For normal conditions, two limits need to be satisfied. The limit for the ordinary person is ES1 and the instructed person is ES2. The limit under single-fault condition is ES2.

|

| Touch Temperature |

Handle and enclosure temperature are only measured during normal operation.

Touch temperature can be measured at any ambient.

The limits do not specify time. It simply states: “touch for a short period.”

|

Handle and enclosure temperature are to be measured during normal operation, abnormal and single fault conditions.

Touch temperature limits are based on measurements in a room ambient of 77 deg. F (25 deg. C). Touch temperature requirements vary for ordinary, skilled, or instructed persons with prescribed safeguards for each category. The standard also takes into consideration anticipated duration of contact with accessible parts.

|

| Electrical Strength |

Electrical strength (Hipot) test voltage is selected based on either Peak working voltages or Required withstand voltage.

|

Test voltage is determined based on the highest value among Transient Voltage, Peak working voltage and Temporary overvoltage as defined within the standard. If using DC test voltage, the standard requires the test to be performed in both polarities.

|

Conclusion

Organizations looking to invest in any IT products in their workplace should look for products with a true UL certification. A UL certified product illustrates a business’s dedication to consumer safety as well as the quality of products. It also adds a layer of protection and accountability in the event an insurance claim needs to be made.

As technology changes, the standards need to move along with them. UL 62368 sets the latest technology standards for information technology and audiovisual products. A more performance-oriented, hazard-based approach under the new standard ensures a higher level of peace of mind.

References

- UL 62368-1, 2nd Edition

- UL 60950-1, 2nd Edition

- “IEC 62368-1: What can we expect”, by Homi Ahmadi, July 30,2019

- UL Brochure – Compliance to IEC62368-1, The New Hazard Based Safety Standard

Posted by Ashish Moondra, CPI Sr. Product Manager, Power, Electronics & Software at 10/15/2020 10:59:54 AM